Empowering Women

• Nokia-Karavan Craft Centres

• Destiny Roti

• Solar Food Dehydrator

In the post-disaster period women have been the worst sufferers, huddling inside their cold tents or emergency shelters during winter, which, after the onset of summer, became equally unlivable hot ovens. It was clear to us that if any section of society would continue to suffer most, it would be women, who would have to pay for the slow recovery in the next years. During the early post-disaster days, we believed that ways had to be found in order that women could lead the recovery effort by providing livelihoods through the skills that they were familiar with or could be trained for. From conversations it became clear to us that women were keen to generate a decent income and were more likely than men to be involved immediately in productive work.

Nokia-Karavan Craft Centres (NKCC)

The beadwork of Kodar Village in the Siran Valley is traditionally crafted by women. In this deprived and marginalized community, living in remote mountainous terrain, with only a few houses on each hillock, the most important jewellery for women consists of elaborately crafted necklaces, hand and finger lacy covers, bracelets etc. The beads, although comparatively in-expensive, lend themselves to innovative designs as cultural expressions of those living in isolated communities. The bead jewellery reflects the status of women and young girls in life and community.

First women's assembly at the orchard in Kodar Bala.

After the first-ever women’s gathering organized by the Progamme in early May 2006, attended by over 150 women in Kodar Bala, it was evident that women were keen to begin productive activities. Their most vocal demand was for sewing machines. The beadwork they considered of little value, never having used it except as an adornment for themselves.

Following our philosophy of encouraging self-reliance among the affectees, women were asked to form groups of 10-12 households, the one that offered a common space to work together would be the team leader and eligible for a sewing machine. Thus, literally at no cost the craft centres were established. Women were asked to start bracelet production by utilizing simple designs. In order to retain authenticity and the spirit of ‘one –of-a-kind’ they are encouraged to use their traditional designs and colour combinations. All the products are purchased by the programme. Beginning with five craft centres in mid June and a production of 12 bracelets in the first two weeks, by mid-December the 2-week production increased to 800 in 17 centres located at dispersed hilltops. Today there are 55 craft centres and the production is increasing exponentially. Almost 500 women are productively engaged in bead craft, producing over 5,000 bracelets per month and for the first time in their life, have received cash in their hands.

No-cost Nokia-Karavan Craft Centres.

The programme has been carried out from the Project camp office at Kodar Bala. Design, sorting and packaging is carried out at HF head office, Karachi. The ‘Destiny Bracelet’ is being marketed around the world through Nokia and HF friends.

The program has been highly successful in empowering local women and providing them an opportunity to enjoy life on an equal basis.

Due to their newly discovered earning capacity, among the benefits of the programme are greater confidence among women and their increased status in the eyes of men. This program, which started with involving women, has led the way for engaging men of the area into productive community participation activities.

Destiny Roti - Cornbread for Health

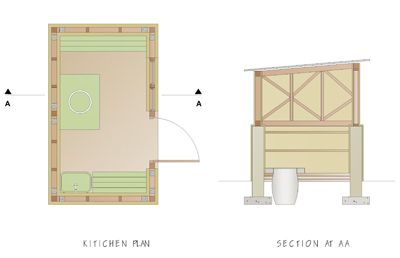

Work on the construction of 10 ‘Destiny Roti’ kitchens has been taken in hand in Kodar in November 2007. The marketing of the ‘Destiny Roti’ is scheduled to be launched in April 2008.

Plan and section of Destiny Roti Kitchens, rendered by Zulfi.

The first ten women participants of the program are:

Imtiaz, Rukhsana, Zaifoon, Mehrunnisa, Shabana, Shaheen, Akbarjan, Parveen, Suhaajan and Begumjan.

The project has been designed in order to develop a sense of ownership and pride. While materials are being supplied to the participants, 25% of the cost in the form of labour and some material available with them is their contribution; almost 50% of the cost of each unit is being given as a grant by I-Led, while the remaining costs, technical guidance and general administrative costs are being borne by the HF-NSN-Nokia partnership. Due to the severe winter and heavy snowfall, coupled with unsettled condition in the country, the progress on kitchen construction has slowed down; however, they are expected to be completed in February 2008. The following pictures show the progress of kitchens in mid-December 2007.

Solid masonry walls upto 3'0" height.

Upper part of the walls are of traditional 'dhajji' construction.

Image showing 'dhajji' supports and roof joists and purlins.

In the Siran Valley, the staple food of the communities is cornbread which is made from local maize traditionally ground in water mills. This particular grinding is credited with the special flavour found in the cornbread (makai ki roti) of the area. The women of the area are particularly skilled in making extremely tasty cornbread, which is baked in the traditional earth ovens. The bread of Kodar has been rated as among the best ever tasted by foreigners who partook of this food after the earthquake. Being a product particularly desirable for healthy lifestyle, it is intended to develop a chain of bread making and packaging mechanism at the community level and transporting and marketing to urban centres e.g. Islamabad, and later, Lahore and Karachi. The product is a highly desirable food product and is much sought after in enlightened circles. If handled in an efficient manner with assurance of hygienic safeguards and rapid delivery, the activity can bring huge dividends to the isolated and remote communities affected by the earthquake.

Plan of Packaging Centre for Destiny Roti, rendered by Zulfi.

Who are the participants?

The activity is being planned for women belonging to the Nokia-Karavan Craft Centres, who have proved their entrepreneurial capability in developing their bead making skill and now feel confident and empowered. Those with greater corn bread making skill will be given preference.

How will it be organized?

• Selected women will be helped to build their own kitchens (for earthen ovens) and provided with the necessary storage and utensils.

• Workshops will be conducted to apprise the participants regarding personal hygiene and imposition of hygienic conditions for production of corn bread.

• Bread will be transported in closed containers to the packing centre.

• A purpose built packing centre will provide the requisite hygienic conditions for vacuum packing and sterilization in food grade pouches

• Cold chain will be established through cold storage and transportation in specially fitted air conditioned vans to Distribution Centre in Islamabad

• Delivery of the bread will be arranged to selected points and health food stores/restaurants

What is the outcome?

Revival/rehabilitation/reconstruction of traditional water mills

The encouragement which is likely to be the outcome of large-scale production is intended to ensure that the traditional water mills, many of which have collapsed, could be revived. Because of their location in the midst of picturesque streams, the area could also be developed as scenic picnic spots.

Continuing use of traditional earth ovens

The earth ovens, which have been traditionally used for centuries will also survive, thus, continuing the tradition which is important to conserve the rich heritage of the area.

Respect for women for making lowly bread

Women will be enabled to earn from a skill that has been considered useful only for the family, thus increasing their status in life and community and empowering them to become more productive members of society.

Hygienic methodologies for household usage

Once trained to use hygienic means of production and emphasis on personal hygiene, the activity is likely to help in achieving better hygienic conditions in the house with concomitant advantage of better health for the entire family.

Solar Food Dehydrator

A solar food dehydrator has been installed in Kodar to try out its application at this remote hilly village. The dehydrator has been designed by Saad Khan of Pak-Swiss Society based in Switzerland and donated to us for trial purposes.

The dehydrator was fabricated through the help of Dr. Afzal of Kahuta Research Laboratories and brought to Kodar for installation. Four women in the community were asked to place sliced vegetables and fruit in trays allocated to them. The initial experiments have yielded extremely positive results. The dried vegetables and fruit have retained their flavour and have been much appreciated by the community.

However, since the dehydrator is rather expensive (Rs. 35,000), we had requested Saad Khan to design an inexpensive version in order that each family could have its own dehydrator in the vicinity of its home. He has performed a commendable task of designing one which be extremely economical (under Rs. 4,000). A prototype was constructed at our camp office in Chattar under the guidance of Saad Khan in November 2007. Due to heavy snow and a severe winter, the drying experiment will be carried out after the winter season is over. The cheap version of the dehydrator is envisaged as a do-it-yourself kit which can be easily assembled by the families themselves, and be useful as an alternative to the drying arrangement they had on their flat roofs, which is no longer possible after sloping roofs of galvanized iron have been popularized for earthquake mitigation.

The vegetables and fruit dried through the solar dehydrators are expected to supplement the family income in addition to vegetables and fruit being available for the family's own use. The dehydrators are part of women empowerment programme.

Solar dehydrators being inspected by men and women of Kodar.